Jeju International Airport is the second largest airport in Korea, but as the only international airport on Jeju island, it has recently faced capacity challenges due to the influx of visitors. To overcome this, the Smiths Detection team worked closely with the airport to identify key challenges and fine-tune operations.

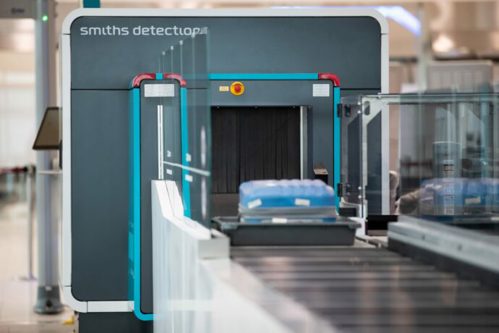

This five-week long process involving security operator system training, test runs with passengers and operators, and system optimisation was critical in decreasing evaluation time and maximising baggage throughput. Because of Korea Airport Corporation’s ambition to lead on the technological front in aviation security, Jeju International Airport installed the Smiths Detection HI-SCAN 6040 CTiX to harness the latest Computed Tomography (CT) X-ray technology for checkpoint screening.

Today, Jeju International Airport is not only better equipped to handle the growing volume of visitors, but also boasts a futureproof security checkpoint.

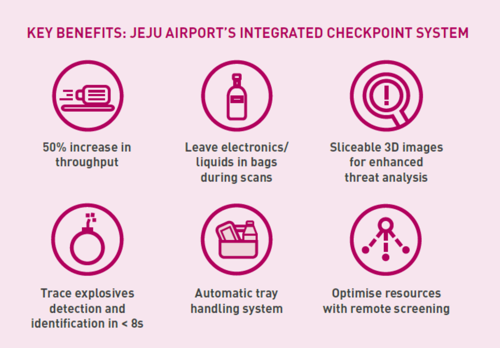

With nearly 80,000 annual flights, Jeju International Airport serves one of the world’s busiest domestic routes¹. To ensure that it was prepared for the next phase of passenger growth, Jeju International Airport sought new and improved solutions that would not only enhance security, but also ensure passenger satisfaction. When it comes to security checkpoints, a global survey reveals that passengers find it most frustrating having to remove personal items and electronics from their cabin bags and having to wait more than 10 minutes² to pass through security. Jeju International Airport conducted an assessment of its current checkpoint system and identified two main challenges that were hindering its ability to deliver a seamless passenger experience. First, the combination of the high-volume of baggage that needs to be screened and the manual process of tray loading and returns created bottlenecks that led to longer queues and wait times for passengers.

Second, the use of 2D X-ray scans meant that laptops, liquids and aerosols had to be removed from carry-on baggage to ensure 2D X-ray images would not be blocked. Poor passenger preparation and packing behaviour compounded the problem. Since some bags must be rechecked, more time is spent at the baggage screening area. The time, attention and energy required of operators to execute such checks would cause stress and fatigue, which could then impact their threat detection accuracy.

With 3D screening, operators can now more easily identify threats than ever before—even if all items, including electronics and liquids, are left in the bags.

A combination of technology solutions and applications from Smiths Detection was implemented to help Jeju International Airport increase its throughput figures, facilitate a higher detection rate, and achieve cost benefits in the process. Built with Smiths Detection’s proprietary CT technology, the HI-SCAN 6040 CTiX cabin baggage screening system offers the highest level of security through image reconstruction algorithms to form 3D X-ray images. The CT gantry rotates at a constant speed as the baggage is carried through the conveyor belt, taking hundreds of X-ray images from 360° angles to create 3D real-time images. This vastly improved the airport’s threat detection accuracy, speed of operations and passenger convenience at the checkpoint.

Smiths Detection’s advanced screening and management platform, Checkpoint.Evoplus, further optimises resource allocation by allowing for a centralised and consolidated operation through sending images from all security lanes to image analysts in a remote location. This maximises the image analysts’ capacity as they are no longer confined to a single lane. The platform is also capable of analysing data from various systems, sensors and components across an entire screening area to generate invaluable insights. These insights make it easier for operators to monitor performance metrics in real-time for faster and more effective decision-making.

Operators were also equipped with the lightweight, portable explosives trace detector, IONSCAN 600, for more accurate detection and identification of a wide range of explosives in under eight seconds. The unit can be relocated while fully operational so operators can react with speed and agility in a broad range of screening environments.

To free up operators’ time, Smiths Detection’s automated tray handling system, iLane.evo, delivers a steady flow of trays which eliminates the need for manual tray sorting, loading and return. Innovations like iLane.evo are good examples of how automation supports operators, not replace them.

Kim Mun Hwan, General Manager, Security Planning, Korea Airports Corporation, said, “Delivering a comprehensive and efficient baggage screening process comes with many challenges. With Smiths Detection’s HI-SCAN 6040 CTiX, we can offer more convenience to passengers and raise our aviation security standards. We are very pleased with the results and look forward to seeing greater impact throughout our operations.”

With Smiths Detection’s innovations and expertise, Jeju International Airport is now better configured to provide a seamless passenger experience, even as the number of visitors continues to grow. Checkpoint operators can now clear 400 to 500 trays per hour—a 50 per cent increase from using conventional 2D X-ray systems. Through this deployment of new technologies, the airport is playing a key role in positioning Jeju Island as a destination of choice.