Using advanced analytics to keep security equipment performing at the highest levels of throughput and availability and the lowest levels of false alarms.

Looking for maximum equipment reliability? Think smart, connected systems

By Matt Regan, Director Commercial Aftermarket, Smiths Detection

No question about it, today’s airports face a host of converging challenges. Airport traffic is quickly growing—so are security threats. Regulations in many countries call for explosives detection system (EDS) machines, typically with computed tomography (CT), to screen all checked baggage for explosives. This equipment needs to perform at the highest levels of throughput and availability and the lowest levels of false alarm rates.

No question about it, today’s airports face a host of converging challenges. Airport traffic is quickly growing—so are security threats. Regulations in many countries call for explosives detection system (EDS) machines, typically with computed tomography (CT), to screen all checked baggage for explosives. This equipment needs to perform at the highest levels of throughput and availability and the lowest levels of false alarm rates.

Most airports have a fleet of EDS machines working simultaneously across different terminals, operating up to twenty-four hours each day. A single scanner malfunction can potentially disrupt the flow of the entire airport, and any unscheduled maintenance creates significant pressure on resources and the network overall.

That is stress no airport operations team wants to manage.

Advanced analytics has the potential to change that. Using the latest in machine sensors and data analytics, airport operations teams can go from reactionary response to proactive planning.

The result? Improved operations, greater efficiency, more convenient maintenance schedules and happier customers.

How the predictive analytics model works

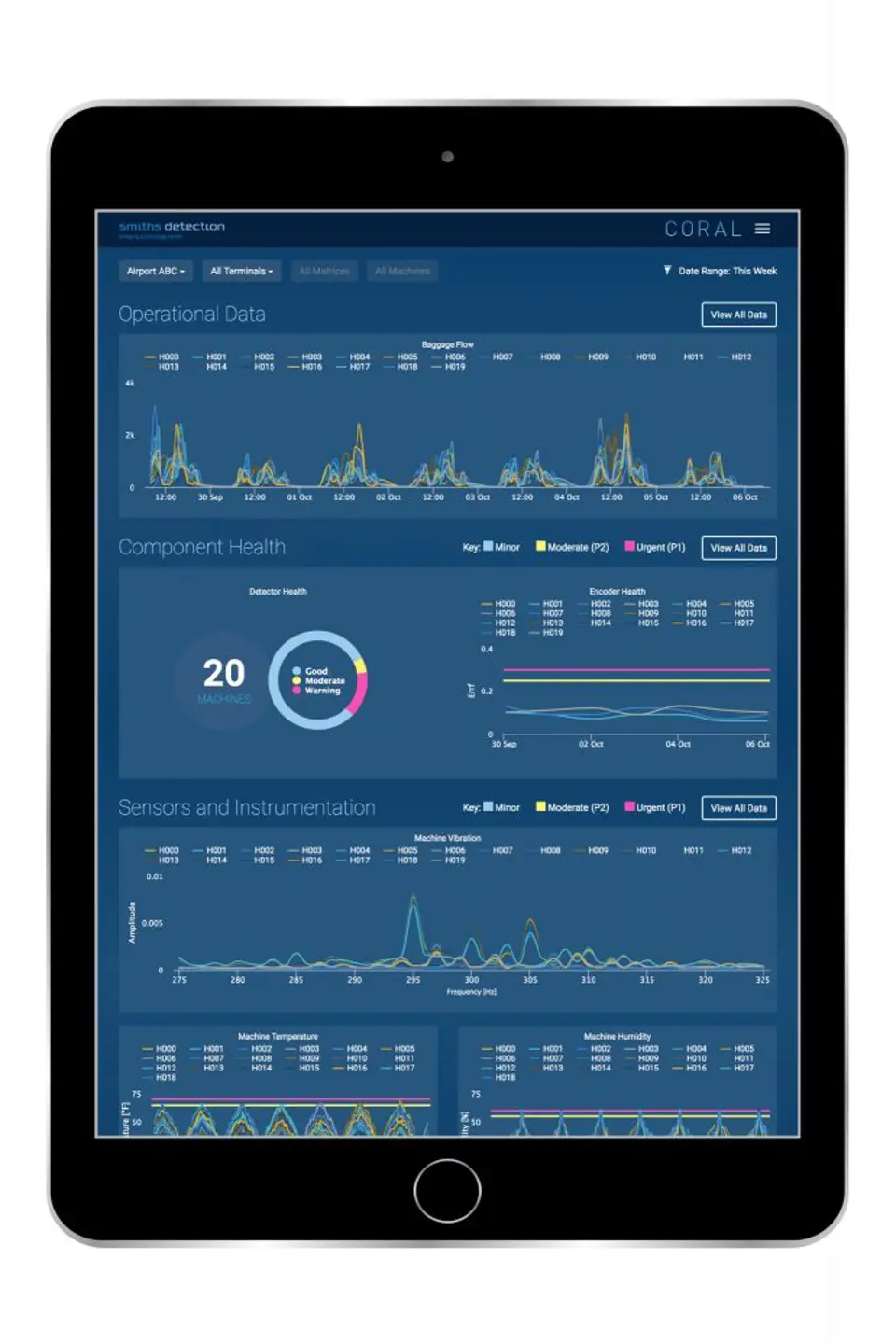

Predictive analytics for airport screening equipment relies on a set of interconnected systems to monitor and gather data and create helpful insight.

Secure remote connectivity retrieves machine performance data automatically. Data can then be sent securely to product and technical support teams for analysis.

Analytic scripts are used to analyse and manage predictively the EDS performance data to pinpoint machine, system and individual component features in advance. Using this information, airports can be alerted proactively to schedule service time, pre-emptively fix problems and reduce both the time to repair equipment and total downtime.

Instrument sensors built into smart machines monitor critical components, which may fail, and capture data. This comprehensive, integrated machine monitoring helps to predict part failures ahead of time. Data collected from multiple machines can be analysed to improve predictive analysis and accelerate preventive maintenance practices throughout the airport.

Remote diagnostics enables system design engineers to investigate the root cause of issues, while also preparing field service teams to arrive on-site with all the necessary parts, tools and knowledge to repair equipment quickly and effectively.

Monitoring dashboards can display the real-time status updates of machine health, site performance and performance trends of machines across the entire airport.

And finally, comparative analytics can show how airport systems compare against peer airports and provide best-in-class performance metrics to enable benchmarking. To protect airport confidentiality, customer data are aggregated, sanitised and only shared anonymously.

Airports using these predictive analytics solutions have already achieved significant improvements, greatly reducing operational downtime and increasing operational availability, while decreasing the mean time to repair (MTTR) and improving the mean time between critical failure (MTBCF).

Technicians can now predict—and prevent—potential failures to keep their airport operations running smoothly, day and night. Even better, turning break-fix emergencies into routine preventive maintenance tasks has improved their relationships with customers across the airport.

That is exactly the kind of progress needed to meet ever-growing passenger traffic and keep airports safe.

To learn more, download our white paper, The Impact of Predictive Analytics on EDS Performance.