Why is rotating CT the best technology for hold baggage screening?

Airport security has come a long way in a relatively short space of time and the arrival of computed tomography (CT) technology across hold baggage, cargo screening and passenger checkpoints is a significant breakthrough in that continuing development.

When choosing CT scanners, a key question is whether to opt for a static or rotating gantry. In some cases, there is no choice. For example, for the recent introduction of CT based screening for passenger hand luggage, only models based on rotating technology have been developed. This suggests that the industry views it as the optimum solution for generating 3D images with the associated data for detecting explosives and other contraband.

With regards to hold baggage and automatic, in-line air cargo screening, both technologies are widely available, with ECAC EDS Standard 3 (and in some cases 3.1) compliance. So why choose rotating rather than static gantries? The straightforward answer is because rotating technology delivers reliability, performance and service – the three key factors to evaluate when choosing explosives detection systems (EDS).

A very reliable option

The medical sector started using CT scanners on patients as early as 1971. Since then the technology has progressed through many stages including various generations of different rotating, fixed or static versions.

Medical applications now almost exclusively use rotating CT gantries. According to radiology specialist, Prof. Dr. Marc Kachelriess from the German Cancer Research Center, “Rotating scanners have reached the point where they have no mechanical issues and offer high availability, consistent data and excellent image quality.”

Having been well tried and tested before being adopted for aviation security, today’s CT equipment has been proven as very reliable. Step changes in bearing design have increased the lifespan of rotating scanners well beyond the replacement cycles typically found in security screening. As a result, they are delivering a high level of availability in many different locations around the world, including on the elevated mezzanines often found in baggage handling systems.

Superior images = superior performance

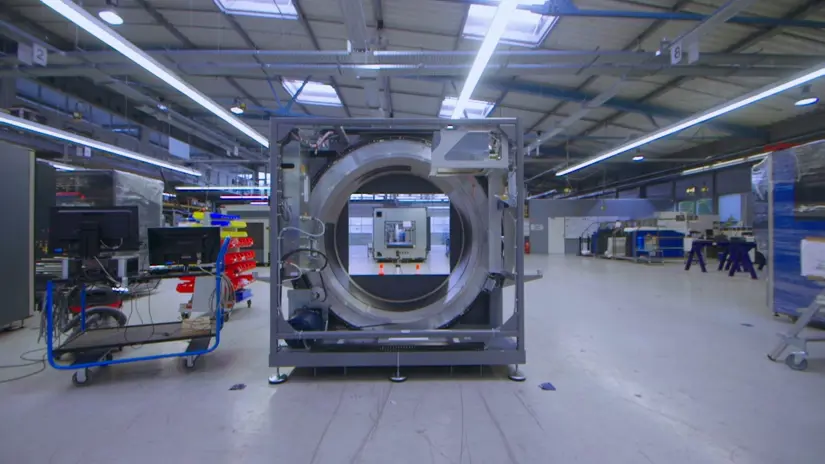

Rotating gantries have a single X-ray tube (essentially a high-powered light bulb emitting photons as X-rays, rather than as visible light) and detectors opposite this tube. They revolve around the object, generating over 700 images which are reconstructed to produce 3D images – more views result in more consistent raw data. A scatter grid is used to minimise image degradation and enable the production of very consistent, high- quality raw data.

As static CT scanners produce fewer views, additional data points have to be created using interpolation. For technical reasons, they cannot use grids and have to address scatter by using a relatively narrow tube. Both of these issues are detrimental to the image quality.

Better image quality supports more accurate detection and provides crisp, highly detailed images for operators, helping them to quickly pinpoint any suspicious items and resolve any alarms – something generally welcomed by government security authorities (BPol, DfT, STAC etc.).

The richness and consistency of the data minimises the false alarm rate, an important issue in airport operations. It also increases the level of detection, opening the door to automatic recognition of threats such as weapons, lithium batteries, gases, liquids and various types of contraband.

“Rotating CT delivers excellent image quality. We need to see much more detail and therefore need a density resolution four times higher than used in security applications,” added Prof. Dr. Marc Kachelriess.

The major benefits of CT stem from the creation of more views, very rich and consistent data and excellent image quality. Therefore to deliver the same level of performance as rotating scanners, static technology would need to be further developed in these areas.

The advantages of a single X-ray tube

From an engineering perspective, the component with the lowest MTBF in any X-ray scanner is the X-ray tube itself. This is an inevitable consequence of continuous screening operations placing demand on the tube and averaging over 20 hours per day, but is a minor issue for the revolving system with its single tube. Increasing the probability of downtime by having multiple tubes (as are found in static CT systems) leads to lower availability. Fewer critical parts and ease of access also makes for simpler maintenance.

Installing any EDS system requires a costly, long-term investment, so it is important to choose systems with built-in upgrade paths. Due to the richness and quality of the original raw data, rotating CT scanners can easily be adapted to meet changing requirements, new security threats or technology developments. This becomes much more complex when dealing with the interpolated data generated by static CT which demands additional processing.

Strong evidence

Rotating CT certainly offers the reliability, performance and service demanded by the aviation industry whereas static technology still needs to evolve in these areas. Rotating is also future-proof and easier to maintain; manufacturers have opted for revolving gantries for the newly introduced checkpoint scanners; and the medical profession relies on them almost exclusively.

Overall, the argument for choosing revolving CT gantries for hold baggage screening is very persuasive.

Ends