Advances in checkpoint lane design make a vital contribution to overall efficiency

Four primary checkpoint components play a critical role in the drive to improve operational efficiency: detection, image management, business intelligence – and an effective lane with tray handling system. This two part article focuses on the key advances in lane design which deliver the increased productivity, higher throughput and improved passenger experience which represent several measures and benefits of optimum operational efficiency. Parallel Divest was covered in the last issue with the attention now moving to Automatic Diversion and Automatic Tray Return.

More focus on customer support

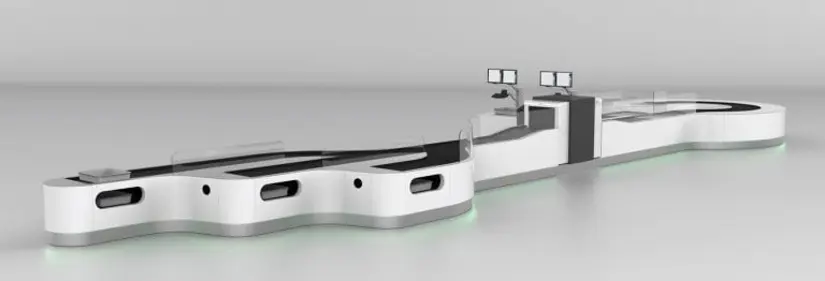

Offering all the benefits of the latest developments in design and technology, the iLane from Smiths Detection takes full advantage of automation. Simple changes to tray handling, such as automated spacing and automatic recirculation back to the start of the checkpoint, have a positive impact on efficiency and put more focus on customer support.

With automated tray spacing, loaders no longer need to separate trays entering the scanners or manually transport them from the end to the front of the lane. That leaves team members free to concentrate on getting passengers ready; supporting them through divestment; and helping them become familiar with the new process.

To get the best performance from the lanes, people need to understand where to go; what to do; and which items should go in the trays. Good communication between staff and customers is essential. The checkpoint team must be knowledgeable, motivated and fully understand the process as well as how to deal with passengers, particularly when a large number of non-frequent flyers are involved.

Maintaining the flow

With the appropriate system configuration, the iLane can automatically divert the trays generating suspicious images when scanned, taking them off the main (cleared) conveyor towards a secondary search area without interrupting the central flow. There is also a high threat module which can divert particularly suspect items to a third area to await further inspection by skilled and authorised personnel.

If the checkpoint is using remote screening, one or more decision conveyors positioned between the scanners and the diverter give operators additional time to evaluate images. If the time limit given for evaluation is exceeded, the trays in question are automatically sent to the secondary search area. This avoids belt stops and manual intervention and can significantly increase the throughput of the main conveyor system.

A positive conclusion

Lanes have also evolved to improve efficiency at the end of the checkpoint process. The time needed for passengers to reclaim belongings and organise themselves before moving on typically takes twice as long as divestment. New lane layout options featuring several reclaim points help to avoid backlogs.

Developments in lane design and functionality aim not only to improve performance but also create a more relaxing experience for the passenger and can even blend into the look and feel or individual branding of the airport.

Click here for Part One and more about the effects of Parallel Divest on passenger flow.