As threats to security continuously evolve alongside the impact and challenges of COVID-19, now is the time to implement technologies to gain greater efficiencies, move cargo faster and leverage digital assistance.

KEY BENEFITS

- Ensures compliance with new TSA standards

- Reduces need for secondary screening

- Improves safety and efficiency

THREATS & REGULATIONS

Aviation has been on the hardest industries hit by COVID-19. In four months, 4.5 million flights were cancelled, grounding two-thirds of commercial aircrafts and leading to a 40 percent reduction in the capacity to move cargo due to less air travel (IATA Webinars). This has resulted in passenger aircraft being reconfigured to move cargo, helping to mitigate revenue loss for airlines while responding to the continued demand for global movement of goods and cargo. There is more to be done in order to prepare for increases in demand, particularly the requirement to deliver vaccines.

Safety has remained a top priority. To comply with safety regulations, cargo needs to be placed in specific compartments even if the flight is only transporting cargo as dangerous goods cannot be placed in cabin. Starting January 1, 2021, TSA mandates that air cargo operations stop using single-view and utilize dual or multi-view X-ray screening technology. Therefore, companies using grandfathered single-view X-rays are in a race to procure, deploy and train on new dual-view equipment in order to meet the deadline.

WHAT IS DUAL-VIEW SCREENING?

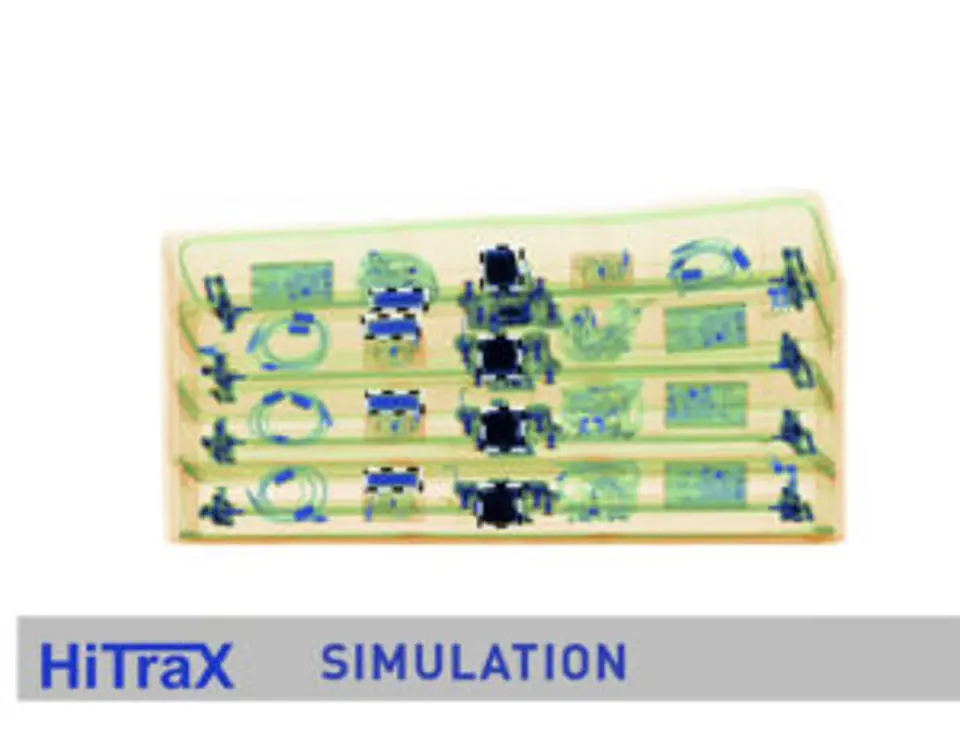

Dual-view screening provides the operator an additional view of screened items allowing for a faster and more accurate evaluation. Dual-view systems use two X-ray generators as opposed to one generator in single view systems showing two views from different angles at the same time. The operator gets a more complete visualization of the actual item and its contents rather than just two flat views. This enables the user to quickly identify and locate potential threats and contraband.

Dual-view technology makes screening more efficient as it reduces the need for operators to re-position the item and re-scan to evaluate anything questionable.

The screened images are stored, improving processes and the flow of information. Indeed, having these images available digitally allows operators to download, transfer them to other machines or share them amongst various sites or with agencies.

5 WAYS AIR CARGO COMPANIES WILL GAIN EFFICIENCIES WITH DUAL-VIEW SCREENING

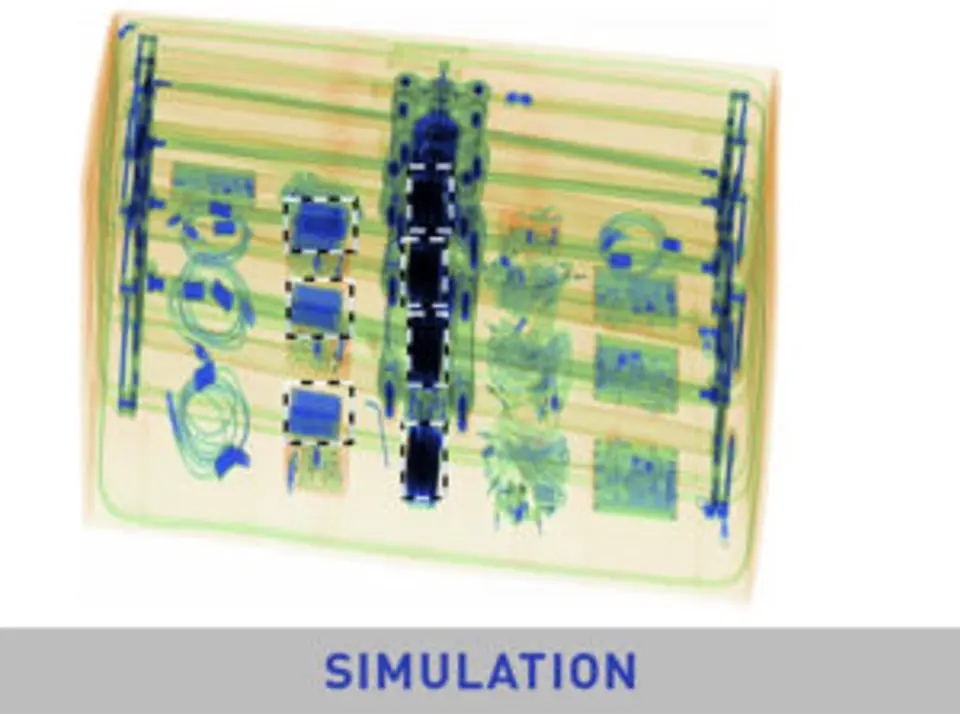

Package scanned through Smiths Detection dual-view screening HS 100100V T-2is detecting Lithium Batteries

1 | TSA Deadline

By January 1, 2021, the TSA requires all air cargo companies to use dual-view screening technology. By upgrading now, cargo operations are insuring systems will be in place and operators will be trained in advance to avoid any unforeseen delays or interruptions.

2 | COVID-19 Impact

There are many new standards for safety due to COVID-19 in the air cargo industry. Using the dual-view screening technology will reduce the need to readjust packages, reducing touch-points between operators and helping reduce potential exposure to employees. Additionally, the dual-view systems come in a variety of sizes. As a result, you can have different sized units adapted to your space to allow for personal distancing.

3 | Increased Safety

Dual-view screening systems produce a clearer image to detect threats and contraband. They show clearer imaging to dense commodities scanned as operators can analyze the package through different angles. Optional upgrades are available based on the types of threats air cargo companies are facing such as lithium battery detection and automatic explosive detection capability*.

4 | More efficient

Dual-view systems will allow better operation by enabling more objects to be scanned. Having an improved view allows the operators to clear more bags at the first screening – reducing the need to rescan and rotate the package multiple times to facilitate reliable inspections of tightly packed objects in one process shortening inspection times.

5 | Ideal installation timing

Due to decreased air travel, air cargo companies are currently not at full capacity. This makes it an ideal time to install new equipment while maintaining personal distancing with fewer interruptions to your service. You will have time to train the operators and be ready to fully operate ahead of the TSA deadline and when air traffic booms again.

* Smiths Detection currently offers the iCMORE Lithium Batteries capability on the 100100V/T-2is. The automatic explosives detection unit is available with the EDS CB upgrades for the 6040-2is and 6040/7555aTix.

Smiths Detection HS 100100V T-2is workstation