Advances in checkpoint lane design make a vital contribution to overall efficiency

Screening equipment cannot reach optimum performance without a steady flow of trays generated by an effective lane. Innovations in lane design and function can help take the overall checkpoint solution to the next level by removing bottlenecks and literally keeping the process moving.

To get the best possible results, lanes should seamlessly integrate into the other checkpoint components; and offer a variety of configurations to meet differing demands. They should also be flexible enough to expand and grow to handle increasing passenger traffic; and like other future-proof checkpoint technologies, have the capability to incorporate new inspection systems and functions such as remote screening.

Longer lanes, for example, can typically support higher throughput but do not alone generate the flow. There is a complex interplay between the different elements which make up the overall process and therefore, it is more important to have a lane of the right proportions to achieve the best outcome for the individual airport. Design and technical developments speed up the process through efficiencies in other areas – sustaining the flow produced at the start and, in many cases, doubling the number of passengers screened per hour.

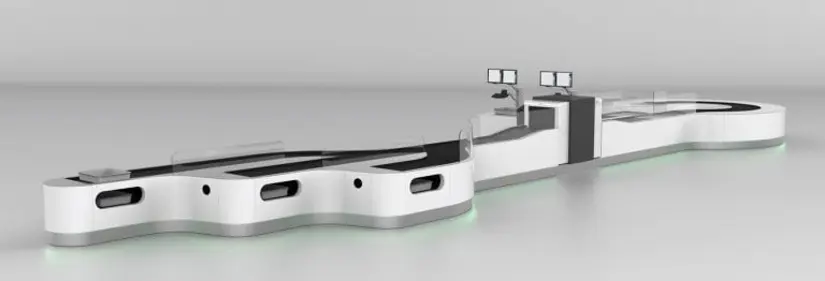

The iLane from Smiths Detection features the latest developments. It offers the three key advances in lane design which together deliver the increased productivity, higher throughput, reduced operational costs and an improved passenger experience which represent the measures and benefits of optimum operational efficiency:

- Parallel divest: a completely different approach to preparing passengers for the screening process

- Automatic diversion: an efficient method of separating suspicious baggage from the main conveyor

- Automated tray return: eliminates the need to transport trays manually

A practical starting point

The security process has, in the past, been a tiresome process for the travelling public with tailbacks right at the outset, as one by one, they wait to remove items and put them in trays. Today, the parallel divestment technique offered by iLane means several people can prepare simultaneously, push their trays into the screening queue and proceed immediately to the body screening stage.

As multiple trays can be filled and fed onto the conveyor at the same time, passengers can start organising their own belongings and move around slower people in front. With the addition of an active conveyor, trays can be pushed on to it for transport towards the scanners as soon as they are ready – eliminating the need to wait for other passengers. The iLane design has also considered the people ‘downstream’ who may not be able to access the conveyor if trays are approaching from further ‘upstream’. Light sensors are used to pause a portion of the active conveyor so ‘downstream’ trays can be added manually.

At the end of the checkpoint, iLane provides valuable space for numerous passengers to reclaim their belongings and get organised before continuing on into the departure lounge – a process which typically takes twice as long as divesting. If necessary, several reclaim stations can be added to avoid any potential backlog.

The next issue of the Aviation Newsletter, will focus on automation and the other two significant design developments: automatic diversion and automated tray.

Click here for Part Two.